| Przeznaczenie i klasa sterownika | |

|

Klasa sterownika |

|

|

Moc silnika sprężarki śrubowej |

|

|

Sterowanie silnikiem trójfazowym w układzie gwiazda-trójkąt |

- |

|

Sterowanie inverterem (falownikiem) |

- |

|

Sterowanie gwiazda-trójkąt oraz inverterem (falownikiem) |

- |

|

Sterowanie inverterem (falownikiem) do 100 Hz |

- |

|

Sterowanie inverterem (falownikiem) do 200 Hz |

- |

|

Bez invertera (falkownika) / pomiar temp. PT-100 |

- |

|

Bez invertera (falkownika) / pomiar temp. PT-1000 |

- |

|

Z inverterem cyfrowym (falkownikiem) / pomiar temp. PT-100 |

- |

|

Z inverterem cyfrowym (falkownikiem) / pomiar temp. PT-1000 |

- |

|

Z inverterem analogowym (falkownikiem) / pomiar temp. PT-100 |

- |

|

Z inverterem analogowym (falkownikiem) / pomiar temp. PT-1000 |

• |

|

Zastąpił sterowniki MS-085 / MS-086 |

- |

|

Zastąpił sterowniki MS-250 / MS-350 / MS-385 / MS-385V24 |

- |

|

Zastąpił sterowniki MS-386FRQ / MS-586FRQ |

- |

|

Procesor i wyświetlacz

| |

|

Klasa procesora |

|

|

Rozdzielczość przetwornika A/C |

|

|

Typ |

|

|

Wielkość |

|

|

Kolorowy / Monochromatyczny |

|

|

Dotykowy |

- |

|

Rozdzielczość |

|

|

Interfiejs graficzny, menu, brand

| |

|

Wyświetlanie wartości cyfrowych |

- |

|

Wyświetlania komunikatów tekstowych |

- |

|

Wyświetlanie tekstowego statusu urządzenia |

- |

|

Wyświetlanie aktualnej daty i czasu |

- |

|

Wygaszacz ekranu z ciśnieniem |

- |

|

Wyświetlanie grafiki i ikon |

- |

|

Wyświetlanie bargrafu ciśnienia |

- |

|

Wyświetlanie wykresów i statystyk |

- |

|

Wyświetlanie diagnostyki i analiz |

- |

|

Ilość diod informacyjnych LED |

|

|

Ilość przycisków na klawiaturze |

|

|

Interaktywny panel dotykowy |

- |

|

Wielojęzykowe menu tekstowe |

- |

|

Odrębne menu użytkownika i serwisowe |

- |

|

Odrębne menu produkcyjne |

- |

|

Standaryzacja struktury menu |

|

|

Standaryzacja numeracji parametrów i błędów |

- |

|

Wersje językowe |

|

|

Indywidualne wersje językowe (OEM) |

|

|

Logo: producenta (OEM) / dystrybutora (D) / serwisu (S) |

|

|

Brand i kolorystyka producenta (OEM) |

|

|

Kontrola parametrów sprężarki

| |

|

Pomiar i kontrola ciśnienia głównego |

- |

|

Pomiar i kontrola ciśnienia sieciowego |

- |

|

Pomiar i kontrola ciśnienia pomocniczego |

- |

|

Pomiar i kontrola ciśnienia zbiornika |

- |

|

Kontrola czujnika ssania VS presostat |

- |

|

Kontrola i ustawienie poziomu asymetrii (analogowe) |

- |

|

Kontrola pasywna stanu asymetrii (cyfrowa) |

- |

|

Kontrola prądu silnika przekładnik / falownik |

- |

|

Kontrola ilości włączeń silnika na godzinę |

- |

|

Kontrola temperatury silnika PTC / NTC |

- |

|

Kontrola temperatury silnika KTY-84 / PT-100 / PT-1000 |

- |

|

Kontrola temperatury silnika |

- |

|

Termik silnika KTY-84 |

- |

|

Termik wentylatora |

- |

|

Wyświetlany bieżący status silnika |

- |

|

Kontrola temperatury oleju PT-100 |

- |

|

Kontrola temperatury oleju PT-1000 |

- |

|

Kontrola temperatury powietrza |

- |

|

Autokontrola czujnika temperatury oleju |

- |

|

Kontrola stanu filtra oleju (OF) |

- |

|

Kontrola stanu filtra powietrza (AF) |

- |

|

Kontrola stanu separatora (SEP) |

- |

|

Kontrola dostępu do menu użytkownika |

- |

|

Kontrola dostępu do odrębnego menu serwisu |

- |

|

Kontrola dostępu do odrębnego menu produkcyjnego |

- |

|

Opcja terminowej blokady sterownika |

- |

|

Kontrola dostępu na kartę zbliżeniową (RFID) |

- |

|

Przycisk bezpieczeństwa / otwarte drzwi |

- |

|

Test zaworu bezpieczeństwa |

- |

|

Obsługa urządzeń i modułów oraz komfort użytkowania

| |

|

Spustu kondensatu (DRAIN) |

- |

|

Wentylatora - funkcja chłodzenia (VE) |

- |

|

Grzałki - funkcja podgrzewania oleju (H1) |

- |

|

Grzałki - funkcja utrzymania temperatury oleju (H2) |

- |

|

Osuszacza - sterowanie osuszaniem (DRYER) |

- |

|

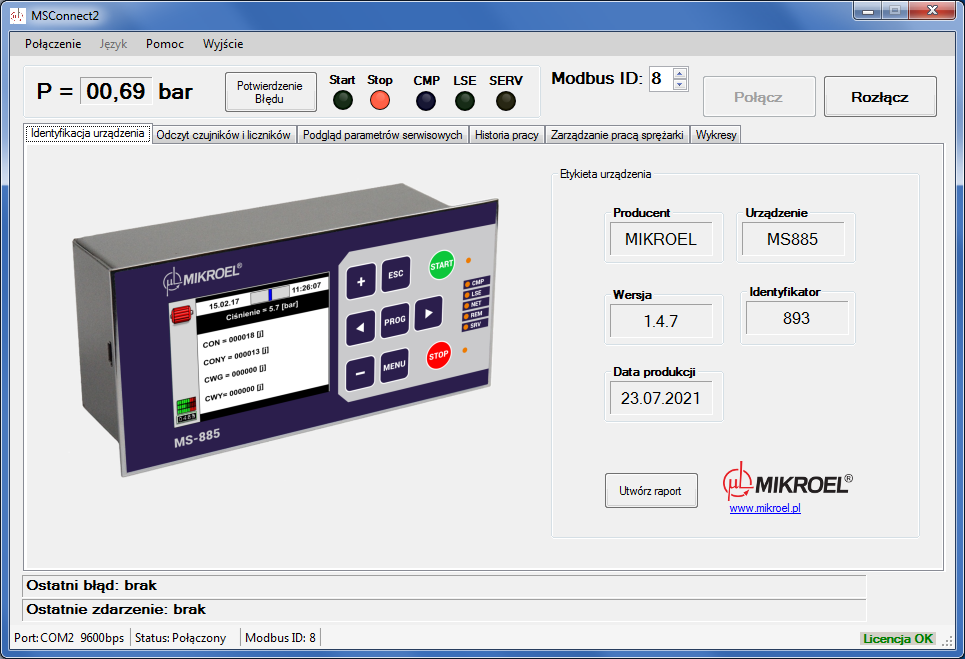

Obsługa modułu wizualizacji MSConnect 2 |

- |

|

Obsługa pamięci zewnętrznej USB |

- |

|

Standard komunikacyjny Ethernet |

- |

|

Obsługa modułu zbliżeniowego RFID |

- |

|

Obsługa modułu komunikacji GSM |

- |

|

Obsługa modułu komunikacji LoRa |

- |

|

Opcja definiowalnego autorestartu |

- |

|

Opcjonalny autorestart po zaniku zasilania |

- |

|

Opcjonalny autorestart po stanach awaryjnych |

- |

|

Opcjonalny autorestart po błędach asymetrii |

- |

|

Automatyczna regulacja czasu pracy luzem TLSE |

- |

|

Obsługa inwertera (falownika) |

- |

|

Odczyt informacji/błędów z inwertera (falownika) na sterowniku |

- |

|

Funkcja kontroli zużycia energii |

- |

|

Funkcja sterowowania odzyskiem ciepła / CO / ciepła woda |

- |

|

Funkcja szybkiej gotowości Ultra Speed |

- |

|

Tryby pracy sprężarki

| |

|

Tryb pracy autmatycznej (AUTO) |

- |

|

Tryb pracy ciągłęj (CONST) |

- |

|

Tryb pracy lokalnej (LOCAL) |

- |

|

Zegar czasu rzeczywistego |

- |

|

Jednorazowa praca planowa |

- |

|

Tygodniowy praca planowa |

- |

|

Tryb pracy zdalnej (REM) |

- |

|

Wyjście linii potwierdzenia ACK |

- |

|

Wyjście sygnału ERROR |

- |

|

Wyjście informujące o stanie sprężarki (START/STOP) |

-

|

|

Sterowanie sprężarką pomocniczą (SLV REM) |

- |

|

Tryb pracy sieciowej protokołem Modbus RTU |

- |

|

Tryb praca sieciowej podrzędnej (SLAVE) |

- |

|

Tryb praca sieciowej nadrzędnej (SLAVE/MASTER) |

- |

|

Algorytm pracy sekwencyjnej / równomierne obciążenie |

- |

|

Algorytm pracy kaskadowej / opcja ekonomiczna |

- |

|

Funkcja awaryjnego przejęcia trybu Master |

- |

|

Funkcja autorestartu pracy sieciowej po zaniknięciu zasilania |

- |

|

Sterownik nadrzędny tylko z funkcja zarządzania (MASTER) |

- |

|

Wsparcie obsługi serwisowej

| |

|

Liczniki serwisowe zdefiniowane (ilość godzin lub data) |

|

|

Liczniki serwisowe programowalne (ilość godzin lub data) |

- |

|

Funkcja podglądu zmienianych przez klienta parametrów |

- |

|

Lista ostatnich błędów krtycznych (zapisana ilość) |

- |

|

Lista ostatnich błędów niekrytycznych (zapisanych ilość) |

- |

|

Lista ostatnich zdarzeń (ilość zapisanych zdarzeń) |

- |

|

Obsługa zdalnej diagnostyki poprzez MSConnect2 |

- |

|

Test zaworu ssania Y |

- |

|

Test zaworu bezpieczeństwa |

- |

|

Wykrywanie zwarcia w obwodzie 24V |

- |

|

Raport serwisowe (liczniki / błędy / zdarzenia) zapis na USB |

- |

|

Autodiagnostyka sterownika |

- |

|

Funkcja diagnostyki nieszczelności sieci |

- |

|

Zapisywanie / przywracania ustawień ze strownika |

- |

|

Zapisywanie / przywracanie ustawień z USB |

- |

|

Zdalna aktualizacja oprogramowania przez złącze USB |

- |

|

Obsługiwane protokoły oraz Wizualizacje i Webserwery

| |

|

Modbus RTU RS-485 izolowany / nieizolowany |

- |

|

Magistarala CAN |

- |

|

Modbus TCP/IP (Ethernet) |

- |

|

MQTT |

- |

|

Opcjonalna wizualizacja poprzez program MSConnect 2 |

- |

|

Indywidualna wizualizacja dla producenta (OEM) |

- |

|

Opcjonalny webserwer pasywny do podglądu danych |

- |

|

Opcjonalny webserwer aktywny do zmiany parametrów |

- |